Hub and Spoke

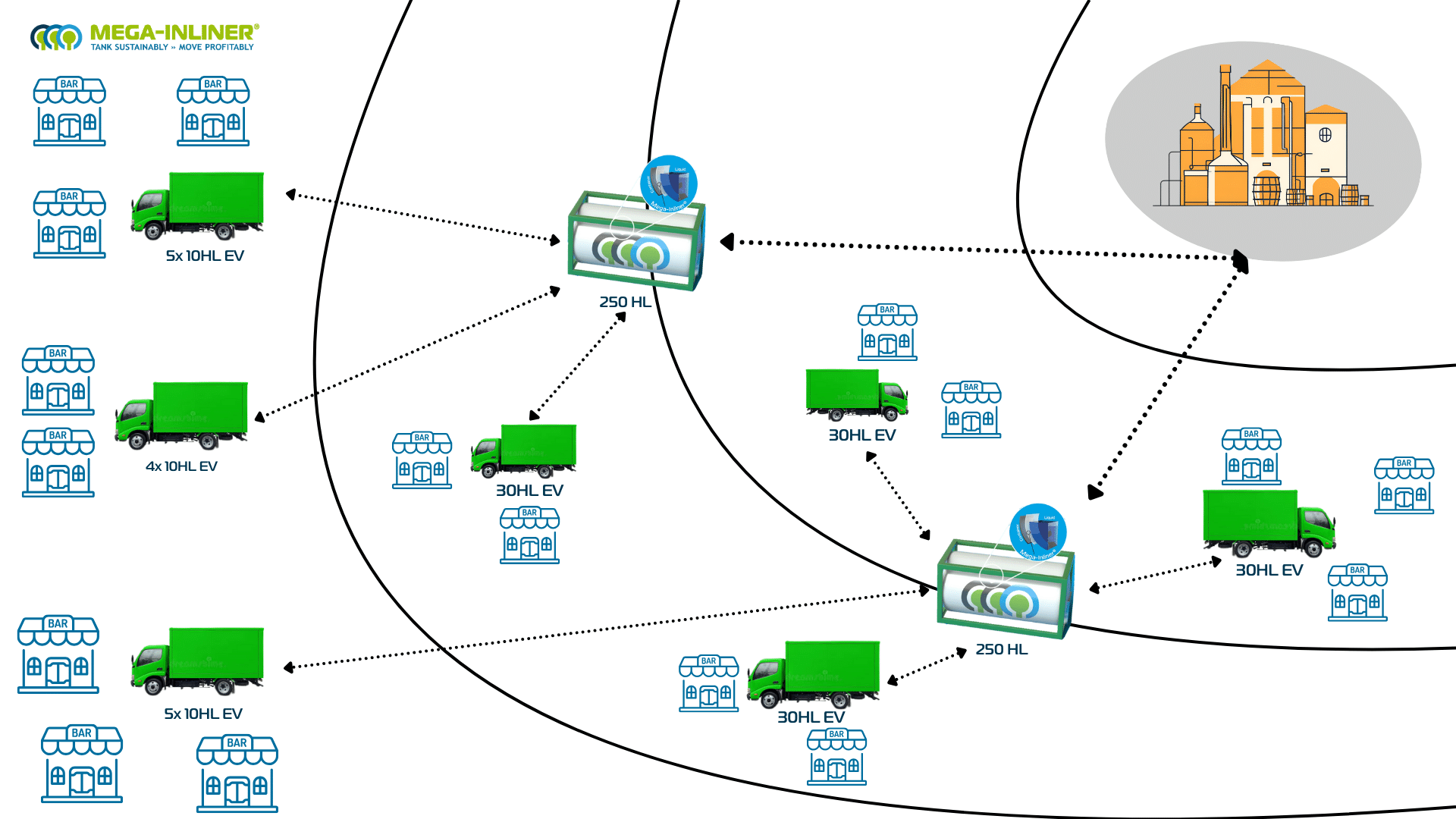

The Mega-Inliner® System is the perfect solution for the hub and spoke model. The best example is the distribution of cellar beer in inner-city areas.

In many countries, cellar beer delivery trucks are becoming smaller due to increasingly stringent city regulations on vehicle weight and emissions. These restrictions aim to reduce traffic congestion and lower carbon footprints in urban areas. However, this change poses a challenge for breweries located more than 50 kilometers away from city centers, as it becomes inefficient to transport small volumes of beer over long distances. The operational costs and carbon emissions associated with multiple trips add up, making traditional delivery models non-viable.

Mega-Inliner offers an innovative Hub and Spoke integration. Instead of sending smaller delivery trucks directly to the brewery, the beer (or other beverages) is transported in bulk to a central hub located near the final delivery destinations. This approach significantly reduces the number of kilometers driven, as bulk transportation is handled more efficiently. From the hub, local, electric delivery vans take over the last-mile delivery, ensuring compliance with urban regulations on emissions and weight limits. Thanks to the Mega-Inliner® the beer (or other beverages) stays in perfect condition, gasses can not escape or enter the product.

This Hub and Spoke model not only simplifies the logistics of cellar beer delivery but also brings multiple benefits:

- Increased sustainability: By reducing the number of trips and using electric vehicles for last-mile deliveries, the overall carbon footprint is minimized. In addition, there is no use of CO2, thanks to the Mega-Inliner® System.

- Cost efficiency: Bulk transport to a hub cuts down on fuel consumption and operating costs, making the process more economical.

- Improved profitability: With lower operational expenses and streamlined logistics, breweries, and distributors can increase their margins while improving delivery standards in quality, costs, and Co2 emissions.

- Compliance with urban regulations: The use of smaller, electric delivery vehicles ensures compliance with local laws regarding emissions and vehicle weight.

By adopting the Mega-Inliner Hub and Spoke model, breweries can adapt to changing urban delivery regulations while improving their efficiency, sustainability, and profitability. This solution is perfect for breweries looking to optimize their logistics while maintaining high standards of product quality, efficiency, and customer satisfaction

Application Benefits

- No oxidation, (de)saturation, or cross-contamination

- No foaming

- No quality loss

- Perfect temperature control

- Ready-to-drink quality

- No use of CO2 pre-pressurizing for loading, just compressed air.

- More volume >> Less kilometres driven

- Co2 reduction & higher efficiency

In Action

Mega-Inliner® is a combination of 2 everyday used bulk transport systems, we bring the best of these 2 worlds together for the best solution available on the market in transporting non-hazardous liquids. An environmentally conscious transport system that reduces Co2 emissions enormously and is also extremely cost-efficient. By using the Mega-Inliner System® planning becomes child’s play when connecting Inbound and Outbound flows.

- 100% product quality,

- No degradation

- No oxidation due to closed system when (un)loading

- No (de)saturation – carbonated products

- Temperature control (from -8c to 71c) , cooling or heating

- Lowest product spill/residue per load

- Lowest Co2 footprint possible per Mt product in total supply chain

- No cross-contamination

- No previous cargo restrictions

- No cleaning or rinsing of the tank, saving water, energy, and chemicals

- No empty kilometres or depot costs

- FDA & EU Food approved

- Halal & Kosher

- Mega-Inliner® 100% Recyclable (single source material)

- Aseptic loading, transport, and unloading possible

- Suitable for storage, longer shelf life

- One-man operation, short lead time

- No people on top of or in the tank.

- Connecting inbound and outbound logistics

Depending on the current supply chain we can be competitive with all. If you are transporting ready-to-drink in bottles now, the impact of using our system is huge, but changing the supply chain takes more time, switching from conventional tank container or flexitank to Mega-Inliner® is easy and gives you the benefits immediately. All other IBCs, Drums, kegs, etc are somewhere in the middle.

By using the Mega-Inliner® System it is possible to go directly to the next loading location without the need for cleaning between each load. Therefore, costs such as driver wages, cleaning costs and waiting time are being saved. Because there will be no residue left behind in the tank all costs of product being wasted are eliminated. Due to our Mega-Inliner®, your product will be shipped in a clean and closed environment and therefore there is no chance of cross-contamination or other problems.

By using the Mega-Inliner® System your Co2 emission will be reduced by a minimum of 30%. The Mega-Inliner® is 100% recyclable and cleaning of the Tank Container becomes obsolete. Our system makes it possible to connect Inbound and Outbound logistics by simply removing the Mega-Inliner® after each load, this results in no empty kilometres to and from cleaning stations, wastage of valuable (drinking) water belongs to the past (saving ± 2,500 litres per cleaning), no chemicals for cleaning are necessary. Ship your foodstuff or other non-hazardous liquids in bulk globally and pack locally save up to 60% on transport costs and reduce a minimum of 30% on your Co2 emission.