With every load, a new Mega-Inliner® is installed to ensure perfect conditions. No risks of cross-contamination, oxidation or (de)saturation

With every load, a new Mega-Inliner® is installed to ensure perfect conditions. No risks of cross-contamination, oxidation or (de)saturation

No expensive cleaning is needed, no empty kilometers, no depot costs and no downtime.

The Mega-Inliner® is produced using a single source material and therefore fully recyclable. With only 15kg of material.

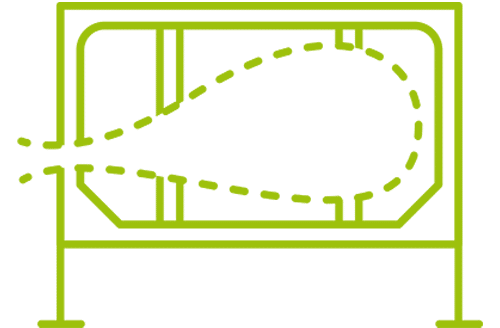

Experience innovative liquid transport with our patented Mega-Inliner® System (Bag-In-Tank), designed for all non-hazardous liquids. The Mega-Inliner® is a high-quality food-grade plastic bag, installed in 5 min. in our Mega-Inliner® Tank Container (MTC).

Protect Your Product

The Mega-Inliner® safeguards your liquid from oxygen and gas exposure, preventing cross-contamination and other logistical risks. This ensures that your product arrives in top condition while keeping the tank container clean.

Efficient Unloading

Using compressed air, our system leaves no liquid behind, and removing the Mega-Inliner® takes only 15 minutes. It’s made from a single material, making it 100% recyclable.

Optimize Logistics and Save

Streamline your logistics by removing the Mega-Inliner® after each load, eliminating prior cargo restrictions and empty kilometers. Save approximately 2,500 liters of water per cleaning cycle and avoid chemical cleaners.

Significant Savings

Switch to the Mega-Inliner® System to save up to 60% on transport costs and reduce CO2 emissions by at least 30%. Choose efficiency and sustainability today!

Intercompany

Hub and Spoke

Events

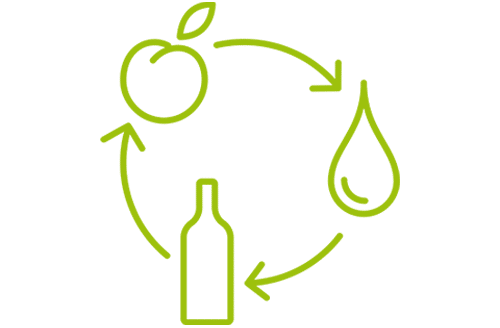

Wine from cellar to bottling plant from local to intercontinental

Ready to drink from production to bottling plant from local to intercontinental

Ready to drink from production to bottling plant form local to intercontinental

Liquids from refine location to production location from local to intercontinental

Liquid chocolate and applications from production to process facility

Dairy and applications from production to process facility

Transport of raw materials intercompany and intercontinental

All non-hazardous liquids not mentioned